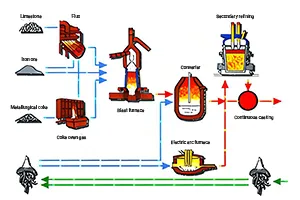

Real-time level measurement of molten steel, slag, and raw material silos under high-temperature conditions

The slag powder levels are often measured using 26 GHz radar transmitters or weight-and-pulley level meters during steel production. However, both of these level measuring methods face limitations in harsh conditions. Negative pressure and heavy dust inside silos can interfere with signal transmission. The 26 GHz radar devices can be equipped with air purging at the horn antenna to remove dust buildup, but long-term operation can often lead to partial blockage. This affects its radar wave emission which causes signal distortion. The mechanical level meters may also experience cable entanglement over time, reducing measurement reliability.

The ADV series and LM78 non-contacting radar level transmitters operate at 76–81 GHz and offer superior penetration and resistance to interference. These sensors maintain accurate readings even in extreme dust conditions. Their lens-type antennas prevent dust adhesion, and the built-in echo locking function enhances reliability at high fill levels by effectively filtering out multiple reflections for precise measurements. Together, these features make the radar level transmitters the ideal choice for measuring material levels in high-dust steel industry applications.

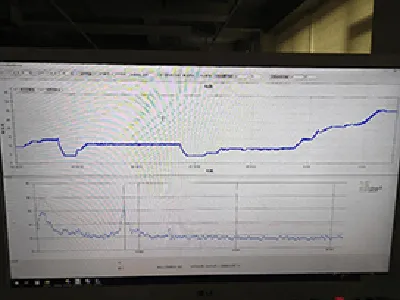

In a steel plant’s slag powder silo, multiple LM78 radar level transmitters (76–81 GHz FMCW technology) were installed due to their ability to provide precise measurements in challenging industrial environments. The radar maintained consistent readings and stable level trends during months of continuous use, demonstrating excellent long-term reliability.

Another steel plant required accurate furnace water level monitoring during high-temperature smelting. Since internal temperatures reached up to 1000°C, non-contact, heat-resistant millimeter-wave radar transmitters were deployed. Equipped with specially designed high-temperature antennas, these units effectively protect internal electronics and deliver precise, stable measurements.

After installation, on-site radar calibration was conducted to determine the zero and full-scale range settings. The resulting waveform curve confirmed normal radar operation and excellent signal performance.

-

- Radar Level Measurement (Liquid & Solid Level Sensor)

- Frequency Range

76 – 81 GHz millimeter-wave radar - Process Temperature

−40 °C to +85 °C / up to +200 °C

- Frequency Range

- Non-Contacting Radar Level Measurement Module The 80GHz millimeter-wave radar module is a key part used in non-contact level transmitters to measure liquids and solids with high precision.

-

- ADV Series Radar Level Transmitter (ATEX/HART/SIL 2 Approved)

- Frequency Range

76 – 81 GHz millimeter-wave radar - Process Temperature

−40 °C / up to +200 °C (maximum)

- Frequency Range

- ADV Series Radar Level Measurement Module They use customized algorithms designed for different working conditions to keep the readings stable, even when the signal is weak or there’s interference around.