Precise non-contact level measurement of corrosive liquids in chemical tanks

Flue gas desulfurization (FGD) is the process of removing sulfur oxides (SO₂ and SO₃) from exhaust gases produced by industrial systems. Since SO₂ is acidic, it can be neutralized by reacting with an alkaline substance, reducing environmental emissions. In a wet FGD system, the alkaline solution or slurry is sprayed into a tower where it meets the flue gas. The SO₂ dissolves in water to form a weak acid solution, which then reacts with the alkaline medium to complete the neutralization process. Accurately measuring these corrosive liquids is challenging because of the harsh chemical conditions and the interference from vapor or foam.

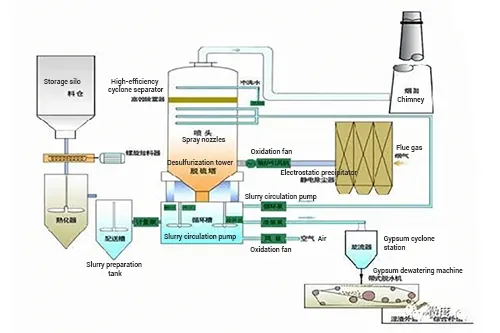

- Storage silo

- High-efficiency cyclone separator

- Spray nozzles

- Desulfurization tower

- Slurry spray system

- Slurry preparation tank

- Slurry circulation pump

- Oxidation fan

- Limestone slurry

- Electrostatic precipitator

- Flue gas

- Chimney

- Gypsum cyclone station

- Slurry pool

- Gypsum dewatering machine

- Finished gypsum

- Air

- Limestone powder

The LM78 non-contacting radar level transmitters, operating at 76–81 GHz, deliver reliable non-contact measurement even in aggressive chemical environments. Their strong signal penetration and resistance to interference make them unaffected by vapor, foam, or corrosive gas. The lens-type antenna helps reduce signal distortion for more consistent readings. In addition, the false echo learning function filters out reflections caused by spray or turbulence, keeping measurements stable and accurate.

A smelting plant in Guangxi adopted a magnesium oxide wet flue gas desulfurization process, using magnesium oxide (MgO) as the raw material. After hydration, it forms magnesium hydroxide (Mg(OH)₂), which acts as the desulfurizing agent. In this system, the magnesium hydroxide storage tank is about 30 meters high, with the radar level transmitter installed approximately 7 meters from the base. The tank connects to a magnesium oxide combustion boiler, where spray nozzles near the wall introduce water. The tank operates under negative pressure, and the measured medium is boiling water. The installation surface is inclined, with a 400 mm mounting pipe that is slightly angled.

Previously, a domestic 26 GHz radar level transmitter was used, but the intense spray and foam in the tank caused significant signal interference, making accurate measurement impossible. After an on-site inspection, our engineers recommended an 80 GHz radar level transmitter for testing. The higher-frequency radar signal can penetrate foam and reach the liquid surface directly, while the false echo learning function effectively filters out interference caused by spray. Because the installation pipe was not perpendicular to the water surface, our engineers used a universal mounting structure to fine-tune the angle and locate the strongest radar signal reflection point before calibration.

After more than a month of continuous testing, the readings stayed closely aligned with the actual liquid level, showing less than 1 cm of error margin. The radar performed reliably earning strong feedback from the customer, and went on to place a large-scale purchase for continued cooperation.

-

- Radar Level Measurement (Liquid & Solid Level Sensor)

- Frequency Range

76 – 81 GHz millimeter-wave radar - Process Temperature

−40 °C to +85 °C / up to +200 °C

- Frequency Range

- Non-Contacting Radar Level Measurement Module The 80GHz millimeter-wave radar module is a key part used in non-contact level transmitters to measure liquids and solids with high precision.

-

- ADV Series Radar Level Transmitter (ATEX/HART/SIL 2 Approved)

- Frequency Range

76 – 81 GHz millimeter-wave radar - Process Temperature

−40 °C / up to +200 °C (maximum)

- Frequency Range

- ADV Series Radar Level Measurement Module They use customized algorithms designed for different working conditions to keep the readings stable, even when the signal is weak or there’s interference around.