Reliable radar level measurement of food products in the storage tank

The food industry is an important link in the “farm-to-table” chain movement that provides safe, nutritious, and diverse food products directly from a farm to a consumer. It covers every stage from raw material processing and production to packaging, distribution, and consumption and is closely tied to public health and quality of life. The industry emphasizes safety first, with strict food safety standards guiding every step of the process to keep products clean, consistent, and high in quality. It also values diversity and innovation, preserving traditional food craftsmanship while introducing healthier, low-sugar, and ready-to-eat products that align with modern lifestyles.

In food processing applications, these radar transmitters complement each other across different stages of production. For hygienic environments such as juice storage tanks and aseptic milk filling lines, the LM78 and ADV series radar transmitters are ideal as their non-contact design eliminates the risk of cross-contamination. For high-viscosity materials like syrup or sauce in reaction tanks or small-capacity vessels, the Guided Wave radar level transmitter provides reliable contact measurement with excellent stability. These reliable level measurement solutions together form a complete level monitoring system that ensures precise control from raw material storage to final product filling, maintaining both safety and efficiency across the production process.

A food additive factory in Jiangsu uses liquid material A as a base, which is heated and stirred at a constant speed in a reactor. During this process, material B is added, and the mixture is concentrated into a thick liquid of specific viscosity before being discharged and dried into powder form. Real-time monitoring of the liquid level inside the reactor is important to maintain safe and efficient production.

Radar level transmitter installation

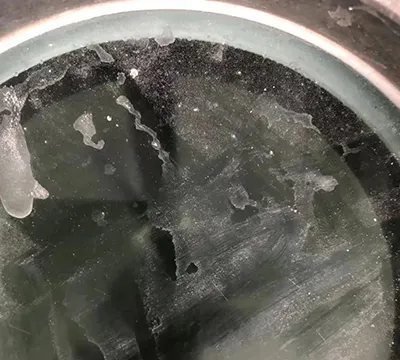

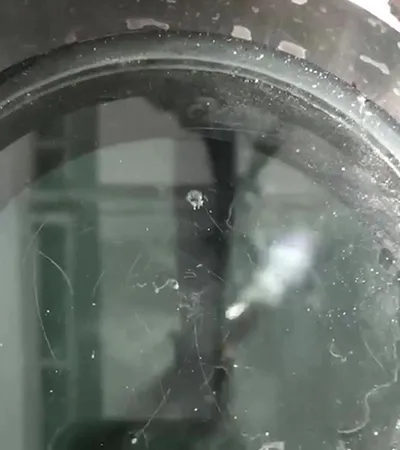

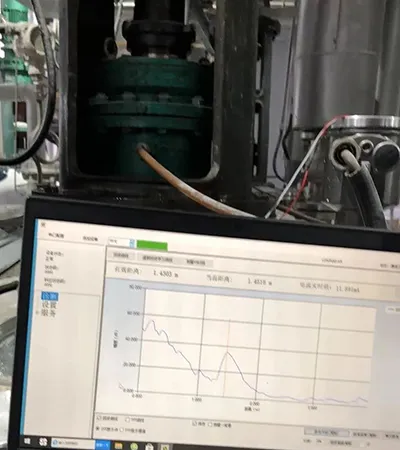

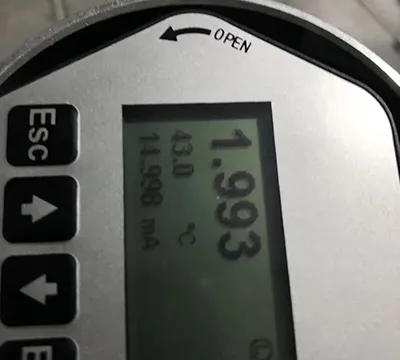

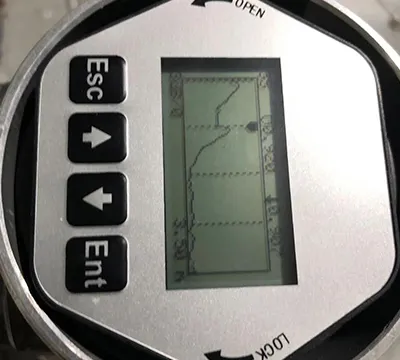

The reactor features a curved-bottom tank with a total height of 2.65 meters, while the internal temperature can reach 130°C. During operation, the liquid is continuously stirred, generating heavy foam and steam. The radar level transmitter was installed 2.75 meters above the base with a DN50 flange connection. The customer had previously tried several types of level transmitters, but none provided stable or accurate readings. They later adopted the 80 GHz high-frequency radar level transmitter. After professional setup and calibration by our engineers, the transmitter was able to deliver precise and consistent level measurements even under these challenging conditions.

Initially, the reactor’s interior was filled with steam and foam, resulting in low visibility.

Following calibration, our technical team conducted on-site training for plant operators, offering key recommendations for daily use. They explained that since the reactor constantly stirs and generates foam, false echo learning should be performed when the tank is empty and stirring, ensuring the radar receives a clean echo signal for accurate real-time measurement during operation.