Radar Level Measurement

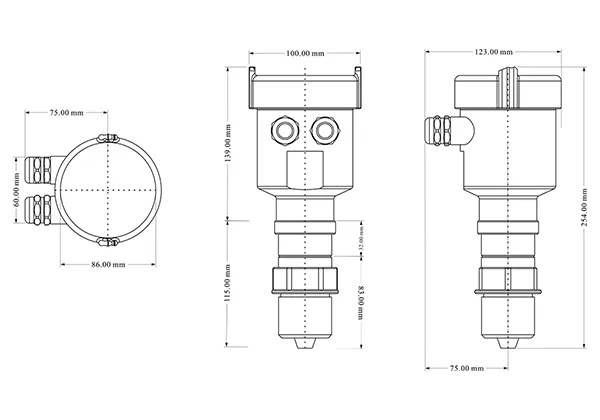

Guided Wave Radar Level Transmitter

Level sensor for continuous level measurement in liquids and solids with guided wave radar (GWR)

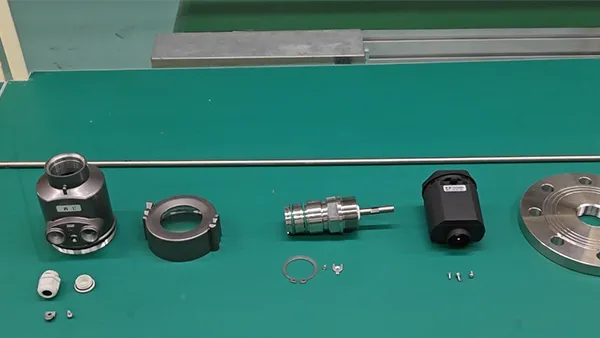

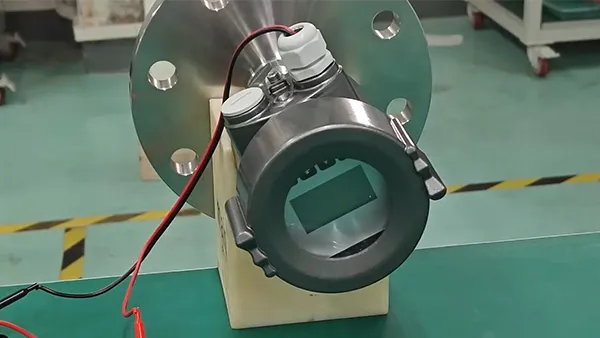

Guided wave radar level transmitters use TDR (Time Domain Reflectometry) technology for continuous, contact-based measurement of liquids and solids. They can be fitted with cable, rod, or coaxial probes to suit different process conditions and require little to no maintenance.

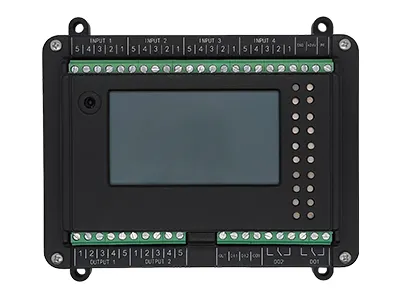

They work reliably even in environments with condensation, foam, buildup, crystallization, or steam. Each transmitter is built with millimeter-wave and waveguide technology optimized for industrial use, offering high accuracy and stable performance over time. They’re also suitable for measuring liquid interfaces and for conditions with heavy vapor or weak signal reflections. Thanks to their advanced signal processing, these level sensors stay accurate even in complex applications. The nonlinear output function can convert radar signals into useful data such as volume, weight, or flow for easy system integration.